Exploring The Creative Potential Of 3D Printing: A Guide To The Most Intriguing Projects

Exploring the Creative Potential of 3D Printing: A Guide to the Most Intriguing Projects

Related Articles: Exploring the Creative Potential of 3D Printing: A Guide to the Most Intriguing Projects

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Exploring the Creative Potential of 3D Printing: A Guide to the Most Intriguing Projects. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Exploring the Creative Potential of 3D Printing: A Guide to the Most Intriguing Projects

- 2 Introduction

- 3 Exploring the Creative Potential of 3D Printing: A Guide to the Most Intriguing Projects

- 3.1 The Materials of 3D Printing: A Spectrum of Possibilities

- 3.2 Exploring the Benefits of 3D Printing: A Revolution in Design and Fabrication

- 3.3 Unveiling the Limitations of 3D Printing: Recognizing the Challenges

- 3.4 Exploring the Impact of 3D Printing: Transforming Industries and Lives

- 3.5 Unveiling the Future of 3D Printing: A Horizon of Innovation and Possibilities

- 3.6 FAQs: Addressing Common Questions about 3D Printing

- 3.7 Tips for Success in 3D Printing: A Guide to Effective Design and Printing

- 3.8 Conclusion: 3D Printing: A Catalyst for Innovation and Progress

- 4 Closure

Exploring the Creative Potential of 3D Printing: A Guide to the Most Intriguing Projects

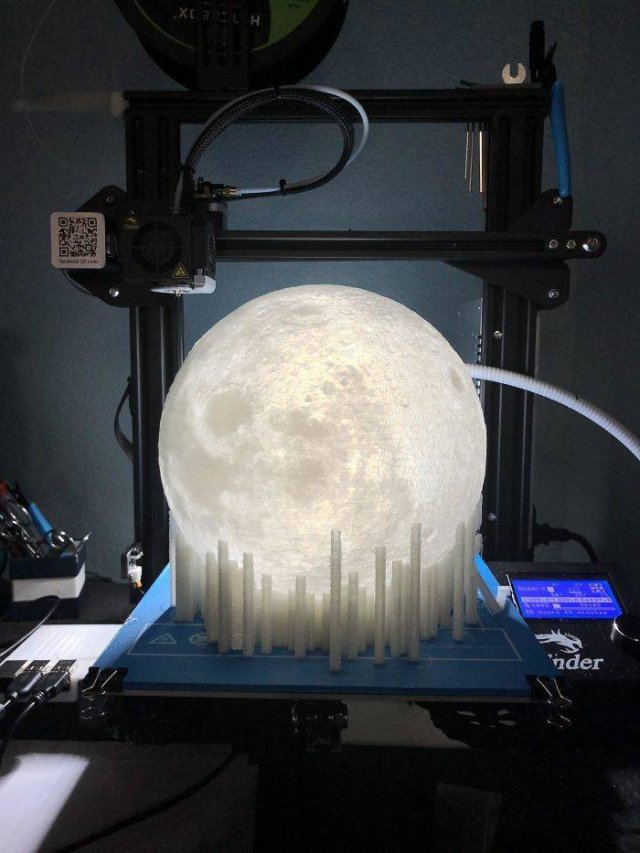

3D printing, also known as additive manufacturing, has revolutionized the way we create and fabricate objects. This technology allows for the construction of complex three-dimensional structures layer by layer, using a digital design as a blueprint. The possibilities are practically endless, ranging from functional prototypes and intricate models to personalized accessories and even medical implants.

This article delves into the realm of 3D printing, exploring its versatility and highlighting some of the most captivating and innovative projects that showcase the technology’s remarkable capabilities. We will examine the various materials used in 3D printing, discuss the benefits and limitations of the technology, and provide insights into the growing impact of 3D printing on various industries and aspects of our lives.

The Materials of 3D Printing: A Spectrum of Possibilities

The choice of material is a crucial factor in determining the suitability of a 3D printing project. Different materials offer distinct properties, influencing the final product’s strength, durability, flexibility, and aesthetic appeal. Some of the most commonly used materials in 3D printing include:

1. Thermoplastics:

- PLA (Polylactic Acid): A biodegradable and bio-based plastic derived from corn starch, PLA is widely used due to its ease of printing, affordability, and relatively low melting point. It’s ideal for prototypes, models, and decorative items.

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength, impact resistance, and durability, ABS is a popular choice for functional prototypes, mechanical parts, and toys. However, its higher melting point requires a heated bed and enclosed printing environment.

- PETG (Polyethylene Terephthalate Glycol): Offering superior strength and impact resistance compared to PLA, PETG is also more flexible and has a smoother surface finish. It’s suitable for containers, enclosures, and durable components.

- Nylon (Polyamide): Known for its high tensile strength, flexibility, and chemical resistance, nylon is commonly used for gears, bearings, and other high-performance parts.

- TPU (Thermoplastic Polyurethane): This flexible and durable material is excellent for creating soft, rubber-like objects, including grips, seals, and flexible electronics.

2. Photopolymers:

- Resin: Liquid photopolymer resins are cured by UV light, offering high resolution and intricate detail. They are commonly used for jewelry, miniatures, and dental models.

3. Other Materials:

- Metal: 3D printing with metal is gaining traction, allowing for the creation of complex metal parts with intricate designs, often used in aerospace, medical, and automotive industries.

- Ceramic: 3D printing with ceramic offers high-temperature resistance and durability, making it suitable for creating intricate ceramic objects and prototypes.

- Composite Materials: Combining different materials, like carbon fiber or glass, with plastics can enhance the strength and performance of 3D printed parts.

Exploring the Benefits of 3D Printing: A Revolution in Design and Fabrication

The rise of 3D printing has brought about a paradigm shift in the world of design and manufacturing, offering a plethora of benefits that are transforming various industries and aspects of our lives.

1. Rapid Prototyping and Design Iteration: 3D printing enables rapid prototyping, allowing designers and engineers to quickly create physical models of their designs and test them in real-world scenarios. This iterative design process accelerates the development cycle, reducing time to market and fostering innovation.

2. Customization and Personalization: 3D printing allows for the creation of highly customized and personalized products, tailored to specific needs and preferences. This opens up new avenues for product design, enabling the production of unique items that cater to individual requirements.

3. Reduced Manufacturing Costs: 3D printing eliminates the need for traditional tooling and molds, significantly reducing manufacturing costs, especially for small-scale production runs and customized designs. This makes it particularly advantageous for startups and small businesses, enabling them to produce high-quality products without significant upfront investment.

4. On-Demand Manufacturing and Decentralized Production: 3D printing facilitates on-demand manufacturing, allowing for the production of goods only when needed, minimizing waste and inventory management challenges. This also enables decentralized production, bringing manufacturing closer to consumers and reducing transportation costs and lead times.

5. Enhanced Functionality and Complexity: 3D printing allows for the creation of complex designs with intricate geometries, impossible to achieve through traditional manufacturing methods. This unlocks new possibilities for product functionality and performance, enabling the creation of lightweight, strong, and highly efficient structures.

6. Sustainable Manufacturing: 3D printing promotes sustainable manufacturing practices by minimizing waste and reducing material consumption. It allows for the production of products tailored to specific requirements, reducing the need for excess inventory and minimizing the environmental impact of manufacturing.

Unveiling the Limitations of 3D Printing: Recognizing the Challenges

While 3D printing offers a vast array of benefits, it’s crucial to acknowledge its limitations, which can influence its applicability in certain scenarios.

1. Limited Material Options: Compared to traditional manufacturing processes, the range of materials available for 3D printing is still relatively limited. While the selection is constantly expanding, certain materials, like high-performance alloys, are still challenging to print effectively.

2. Production Speed and Scale: 3D printing can be slower than traditional manufacturing methods for large-scale production runs. The speed of printing can also vary depending on the complexity of the design and the size of the object.

3. Surface Finish and Accuracy: While 3D printing offers high resolution and detail, the surface finish of printed objects can sometimes require post-processing to achieve a smooth and polished look. The accuracy of the printed object can also be influenced by factors like the printing process and the material used.

4. Cost of Equipment and Maintenance: 3D printers can range in price from a few hundred dollars to tens of thousands, depending on the technology and capabilities. Maintaining and operating a 3D printer can also incur additional costs, such as filament or resin purchases and occasional repairs.

5. Intellectual Property Protection: The ease with which 3D printing allows for the replication of designs raises concerns about intellectual property protection. Unauthorized copying and distribution of designs can pose challenges for creators and businesses.

Exploring the Impact of 3D Printing: Transforming Industries and Lives

3D printing is not just a technological advancement; it’s a transformative force that is reshaping industries and influencing various aspects of our lives.

1. Healthcare: 3D printing is revolutionizing healthcare by enabling the creation of personalized medical devices, implants, and prosthetics. It allows for the production of custom-fit implants and prosthetics that are tailored to individual patients, improving their comfort, functionality, and recovery outcomes.

2. Education: 3D printing is finding its way into classrooms, providing students with hands-on learning experiences and fostering creativity and innovation. Students can design and print their own models, prototypes, and even functional objects, enhancing their understanding of design, engineering, and manufacturing principles.

3. Aerospace: 3D printing is playing a crucial role in the aerospace industry, allowing for the creation of lightweight, strong, and complex components for aircraft and spacecraft. It enables the production of customized parts with intricate geometries, reducing weight and improving fuel efficiency.

4. Automotive: 3D printing is transforming automotive manufacturing by enabling the creation of complex and customized parts, reducing tooling costs, and accelerating prototyping. It’s also used for producing personalized accessories and custom-designed components for vehicles.

5. Architecture and Design: 3D printing is enabling the creation of intricate and complex architectural models, allowing architects to visualize and showcase their designs in a tangible way. It’s also being explored for the construction of buildings and structures, offering possibilities for sustainable and innovative construction methods.

6. Fashion and Jewelry: 3D printing is revolutionizing the fashion and jewelry industries, enabling the creation of unique and customized designs. It allows for the production of complex and intricate jewelry pieces, as well as personalized clothing and accessories.

7. Food and Agriculture: 3D printing is being explored for its potential in food production, allowing for the creation of personalized and customized food items. It’s also being used for creating specialized tools and equipment for agriculture, improving efficiency and sustainability.

Unveiling the Future of 3D Printing: A Horizon of Innovation and Possibilities

3D printing is a rapidly evolving technology with a bright future. The development of new materials, advanced printing processes, and innovative applications will continue to expand its capabilities and impact on various industries and aspects of our lives.

1. Material Development: The development of new materials with enhanced properties, like biocompatibility, conductivity, and strength, will open up new possibilities for 3D printing. This will enable the creation of products with improved functionality and performance, expanding the technology’s applications in various fields.

2. Advanced Printing Processes: Research and development in advanced printing processes, like multi-material printing, 4D printing, and metal printing, will further enhance the capabilities of 3D printing. These advancements will allow for the creation of more complex and functional objects, pushing the boundaries of design and manufacturing.

3. Integration with Artificial Intelligence: The integration of artificial intelligence (AI) with 3D printing will revolutionize the design and manufacturing process. AI algorithms can analyze design parameters, optimize printing processes, and even generate new designs, enhancing efficiency and innovation.

4. Personalized Medicine and Healthcare: 3D printing will play an increasingly significant role in personalized medicine and healthcare. The creation of custom-fit implants, prosthetics, and drug delivery systems will revolutionize patient care and improve treatment outcomes.

5. Sustainable Manufacturing and Circular Economy: 3D printing will continue to promote sustainable manufacturing practices by reducing waste, minimizing material consumption, and enabling the production of products tailored to specific needs. This will contribute to a more circular economy, where materials are reused and recycled, minimizing environmental impact.

6. Space Exploration and Colonization: 3D printing will be crucial for space exploration and colonization, enabling the construction of structures, tools, and even habitats on other planets. It will allow for the production of essential materials and components in space, reducing the need for transportation and minimizing resource dependence on Earth.

FAQs: Addressing Common Questions about 3D Printing

1. What is the difference between 3D printing and traditional manufacturing methods?

3D printing, also known as additive manufacturing, builds objects layer by layer, using a digital design as a blueprint. Traditional manufacturing methods, such as injection molding, CNC machining, and casting, remove material from a solid block to create the desired shape.

2. What are the advantages of 3D printing over traditional manufacturing?

3D printing offers several advantages over traditional methods, including rapid prototyping, customization, reduced manufacturing costs, on-demand production, enhanced functionality, and sustainability.

3. What are the limitations of 3D printing?

3D printing is limited by factors like the range of available materials, production speed, surface finish, cost of equipment, and intellectual property protection.

4. What are some examples of 3D printed products?

3D printing is used to create a wide range of products, including prototypes, models, toys, jewelry, medical devices, prosthetics, architectural models, and even food items.

5. How does 3D printing work?

3D printing works by depositing material layer by layer, following a digital design. The process involves using a computer-aided design (CAD) software to create a 3D model, which is then sliced into thin layers. The printer then builds the object layer by layer, using a material like plastic, resin, or metal.

6. What are the different types of 3D printers?

There are several types of 3D printers, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). Each type utilizes a different printing process and material.

7. How can I learn more about 3D printing?

There are numerous online resources, books, and courses available to learn about 3D printing. You can also visit local makerspaces and 3D printing workshops to gain hands-on experience.

8. Is 3D printing a sustainable technology?

3D printing can be a sustainable technology, as it reduces waste, minimizes material consumption, and enables on-demand production. However, it’s important to consider the environmental impact of the materials used and the energy consumption of the printing process.

9. What are the future applications of 3D printing?

The future of 3D printing is promising, with advancements in materials, printing processes, and applications. It will continue to revolutionize industries like healthcare, aerospace, automotive, and construction, enabling the creation of innovative products and solutions.

10. How can I get started with 3D printing?

To get started with 3D printing, you can purchase a 3D printer or visit a local makerspace. There are also online resources and courses available to learn the basics of 3D design and printing.

Tips for Success in 3D Printing: A Guide to Effective Design and Printing

1. Design for Printability: When designing for 3D printing, consider the limitations of the printing process and the material being used. Avoid overly complex geometries, sharp angles, and thin walls that may cause printing issues.

2. Optimize for Support Structures: For overhangs and complex geometries, use support structures to prevent sagging and ensure proper layer adhesion.

3. Calibrate Your Printer: Regularly calibrate your 3D printer to ensure accurate dimensions and consistent print quality.

4. Choose the Right Material: Select the appropriate material for your project, considering its properties like strength, flexibility, and durability.

5. Post-Process Your Prints: Depending on the material and the desired finish, post-processing techniques like sanding, smoothing, and painting can enhance the look and feel of your 3D printed objects.

6. Experiment and Explore: Don’t be afraid to experiment with different materials, printing settings, and designs to discover the full potential of 3D printing.

7. Learn from the Community: Engage with the 3D printing community online and in local makerspaces to share knowledge, learn from others, and troubleshoot any printing issues.

8. Stay Informed about New Technologies: Keep up-to-date with the latest advancements in 3D printing technology, materials, and applications to stay ahead of the curve.

9. Embrace the Possibilities: 3D printing offers endless possibilities for creativity, innovation, and problem-solving. Embrace the technology’s potential and let your imagination run wild.

Conclusion: 3D Printing: A Catalyst for Innovation and Progress

3D printing is a powerful technology with the potential to transform industries, enhance our lives, and shape the future. Its ability to create complex objects, customize designs, and reduce manufacturing costs is revolutionizing the way we design, produce, and consume products. As 3D printing continues to evolve, its impact on our world will only grow, unlocking new possibilities for innovation, creativity, and progress. From personalized medical devices to sustainable construction solutions, 3D printing is poised to play a pivotal role in shaping a more efficient, personalized, and sustainable future.

Closure

Thus, we hope this article has provided valuable insights into Exploring the Creative Potential of 3D Printing: A Guide to the Most Intriguing Projects. We appreciate your attention to our article. See you in our next article!