The Best Of 3D Printing: A Look At Innovative Applications And Their Impact

The Best of 3D Printing: A Look at Innovative Applications and Their Impact

Related Articles: The Best of 3D Printing: A Look at Innovative Applications and Their Impact

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Best of 3D Printing: A Look at Innovative Applications and Their Impact. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Best of 3D Printing: A Look at Innovative Applications and Their Impact

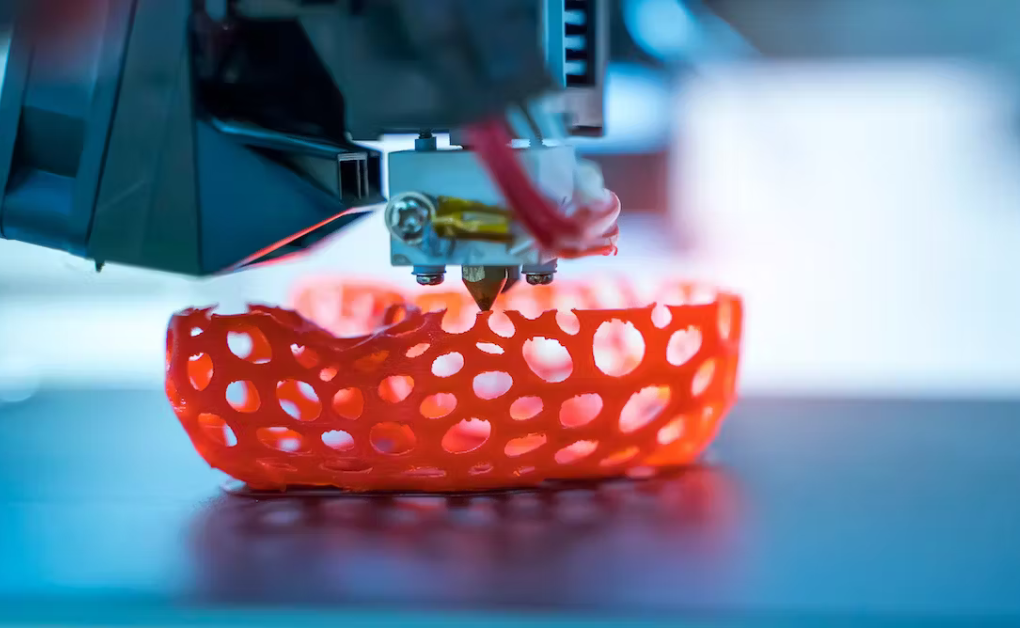

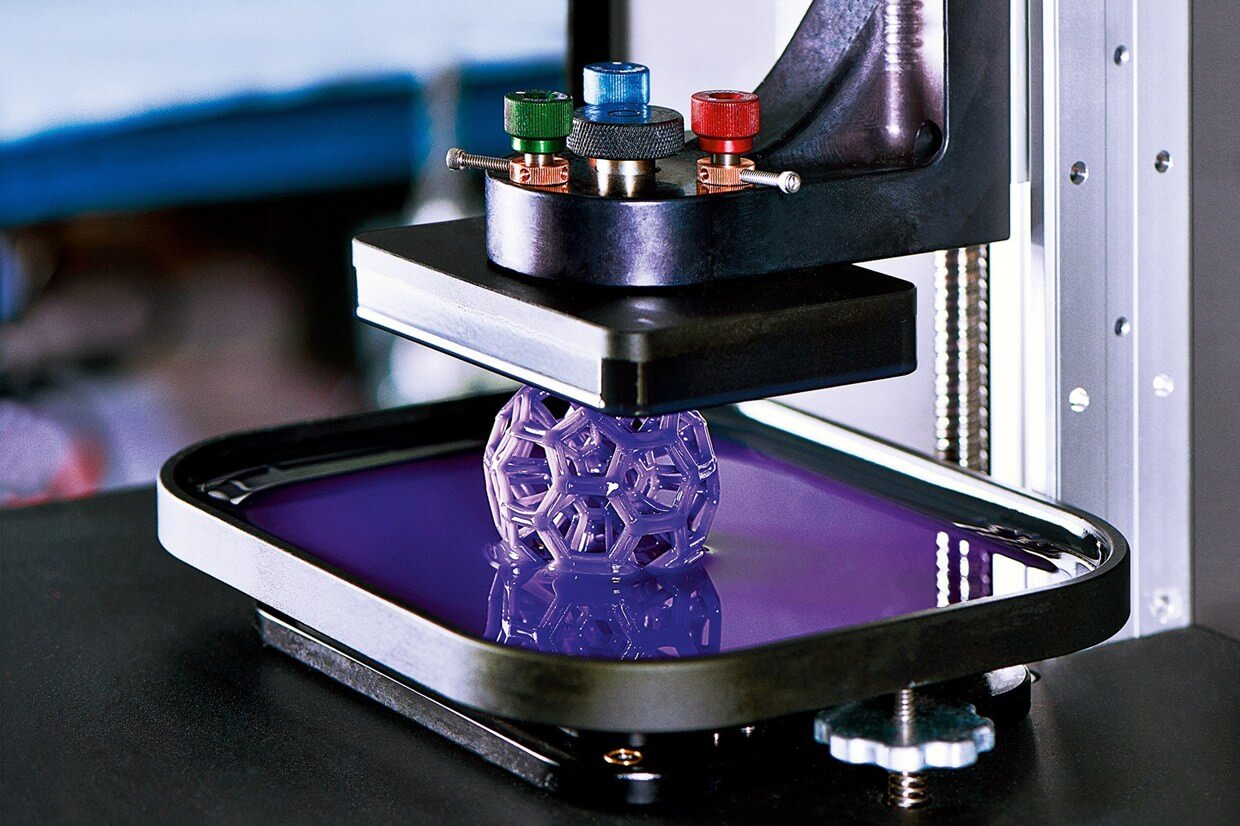

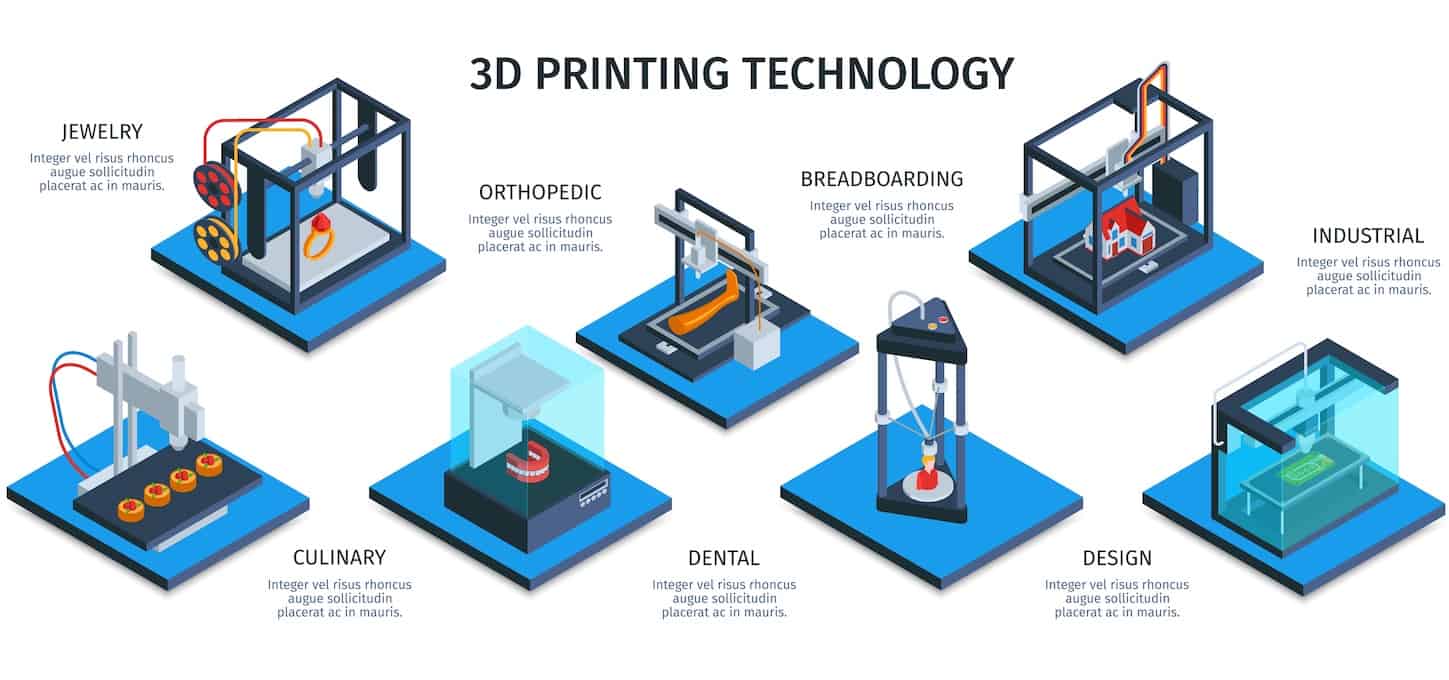

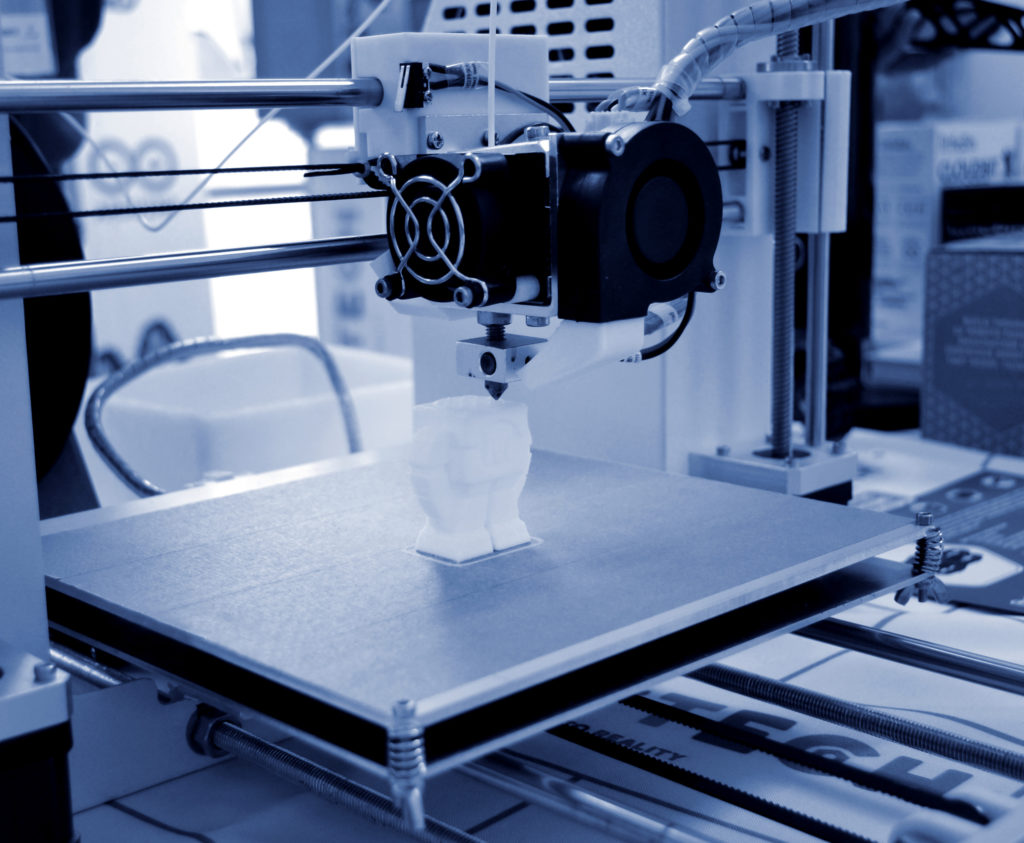

3D printing, also known as additive manufacturing, has rapidly evolved from a niche technology to a transformative force across various industries. This process builds three-dimensional objects layer by layer from a digital design, using materials ranging from plastics and metals to ceramics and composites.

The beauty of 3D printing lies in its versatility. It empowers designers and manufacturers to create intricate geometries, complex internal structures, and highly customized products, all while minimizing waste and offering significant cost savings. This article explores some of the most impactful and innovative applications of 3D printing across diverse sectors, highlighting its potential to revolutionize the way we design, manufacture, and experience the world around us.

Medical Marvels: 3D Printing in Healthcare

The healthcare industry has embraced 3D printing as a powerful tool for improving patient care and revolutionizing medical practices. Here are some notable examples:

- Personalized Prosthetics and Orthotics: 3D printing allows for the creation of custom-fit prosthetics and orthotics, tailored to the individual’s unique anatomy. These devices provide superior comfort, functionality, and aesthetic appeal compared to traditional, mass-produced alternatives.

- Surgical Planning and Simulation: Surgeons can now leverage 3D printed models of patients’ organs and bones to meticulously plan complex surgeries, reducing risks and improving outcomes. These models facilitate pre-operative planning, enabling surgeons to identify potential challenges and develop optimal surgical strategies.

- Bioprinting and Tissue Engineering: 3D printing is playing a pivotal role in the development of bioprinting, a technology that uses biocompatible materials and living cells to create functional tissues and organs. This groundbreaking technology holds immense potential for treating various diseases and injuries, offering new hope for patients with organ failure or requiring tissue regeneration.

- Medical Devices and Implants: 3D printing facilitates the production of complex medical devices and implants, such as stents, bone plates, and custom-designed surgical tools. This technology enables the creation of highly individualized solutions, enhancing patient outcomes and streamlining surgical procedures.

Manufacturing Innovation: 3D Printing in Industry

3D printing is transforming manufacturing processes by enabling rapid prototyping, on-demand production, and customized solutions. Here are some of its key applications:

- Rapid Prototyping and Design Iteration: 3D printing empowers designers to quickly create physical prototypes from digital models, enabling rapid iteration and testing of design concepts. This significantly reduces lead times and allows for faster product development cycles.

- On-Demand Production and Customization: 3D printing facilitates on-demand production, enabling manufacturers to produce parts and products as needed, minimizing inventory and waste. This approach also allows for mass customization, where products are tailored to individual customer specifications.

- Lightweight and Complex Designs: 3D printing enables the creation of complex and lightweight designs, impossible to achieve with traditional manufacturing methods. This opens up new possibilities for product innovation, improving performance, efficiency, and sustainability.

- Tooling and Molds: 3D printing is increasingly used for creating custom tooling and molds, significantly reducing the cost and lead time associated with traditional tooling methods. This approach allows for greater flexibility and agility in manufacturing processes.

Beyond Healthcare and Manufacturing: 3D Printing in Diverse Fields

The impact of 3D printing extends far beyond healthcare and manufacturing, touching diverse fields and shaping the future of various industries:

- Architecture and Construction: 3D printing is revolutionizing the construction industry, enabling the creation of complex and intricate architectural structures, custom-designed building components, and even entire buildings. This technology offers significant benefits in terms of speed, efficiency, and sustainability.

- Aerospace and Automotive: 3D printing is being used to create lightweight and high-performance parts for aerospace and automotive applications. This technology allows for the creation of complex geometries and intricate internal structures, improving fuel efficiency and reducing overall weight.

- Education and Research: 3D printing is becoming an integral part of educational institutions and research labs, providing hands-on learning experiences and enabling the creation of custom models and prototypes. This technology empowers students and researchers to explore new ideas and push the boundaries of innovation.

- Art and Design: 3D printing has empowered artists and designers to create stunning and intricate sculptures, jewelry, and other works of art. This technology allows for the realization of complex designs, pushing the boundaries of artistic expression.

FAQs: Addressing Common Questions about 3D Printing

Q: What are the benefits of using 3D printing?

A: 3D printing offers numerous benefits, including:

- Rapid Prototyping: Enables quick creation of physical prototypes for design iteration and testing.

- Customization: Facilitates the production of highly customized products tailored to individual needs.

- Lightweight and Complex Designs: Enables the creation of intricate and lightweight designs, improving performance and efficiency.

- Reduced Lead Times: Shortens production cycles, allowing for faster product development and delivery.

- Lower Costs: Reduces manufacturing costs by minimizing waste and eliminating the need for expensive tooling.

- Improved Sustainability: Reduces material waste and promotes the use of recycled materials.

Q: What are the limitations of 3D printing?

A: While 3D printing offers numerous advantages, it also has certain limitations:

- Production Speed: 3D printing can be relatively slow for large-scale production runs.

- Material Limitations: Not all materials can be effectively used in 3D printing.

- Surface Finish: The surface finish of 3D printed objects can sometimes be rough.

- Scaling Up Production: Scaling up production can be challenging due to the limitations of current 3D printing technology.

Q: How does 3D printing work?

A: 3D printing works by building a three-dimensional object layer by layer from a digital design. The process typically involves:

- Design: Creating a digital 3D model of the object to be printed.

- Slicing: Dividing the 3D model into thin horizontal slices.

- Printing: Using a 3D printer to build the object layer by layer, depositing material according to the sliced design.

Q: What are some common 3D printing materials?

A: Common materials used in 3D printing include:

- Plastics: ABS, PLA, PETG, Nylon, and PEEK.

- Metals: Aluminum, stainless steel, titanium, and bronze.

- Ceramics: Alumina, zirconia, and silicon carbide.

- Composites: Carbon fiber, glass fiber, and wood fiber.

Tips for Effective 3D Printing

- Choose the right 3D printer: Select a printer based on your specific needs and budget, considering factors such as print volume, material compatibility, and resolution.

- Design for 3D printing: Optimize your designs for 3D printing by considering factors such as overhangs, supports, and print orientation.

- Use the right materials: Select the appropriate materials based on the intended application and properties required.

- Calibrate your printer: Ensure your printer is properly calibrated for optimal performance and print quality.

- Post-process your prints: Clean, smooth, and finish your prints as needed to achieve the desired aesthetic and functionality.

Conclusion: The Future of 3D Printing

3D printing is rapidly transforming various industries, offering groundbreaking solutions across healthcare, manufacturing, architecture, and beyond. Its ability to create highly customized, complex, and lightweight designs, combined with its potential for on-demand production and reduced waste, makes it a powerful tool for innovation and progress. As 3D printing technology continues to evolve, we can expect to see even more remarkable applications and transformative impacts across diverse fields, shaping the future of our world.

Closure

Thus, we hope this article has provided valuable insights into The Best of 3D Printing: A Look at Innovative Applications and Their Impact. We hope you find this article informative and beneficial. See you in our next article!